Published On: Oct 31, 2018

Going beyond Short Circuits

|

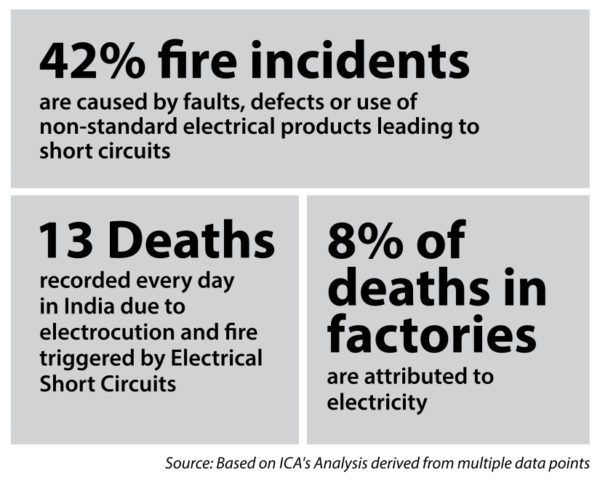

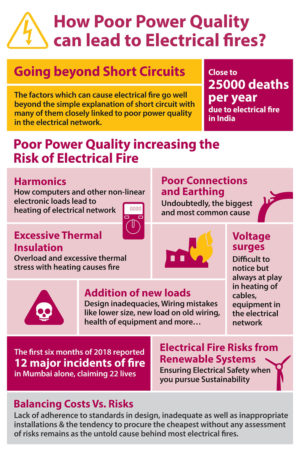

Electrical fires constitute a significant percentage of the total number of building fires, every year. But surprisingly, you will also notice that the underlying reason quoted by most news reports on the cause of the fire is a simple and singular explanation of an electrical short circuit. Perhaps there are reasons, from most evidence being destroyed while extinguishing the fire to probably the convenience of the term ‘short circuit’ that can be commonly understood by everyone. However, it is certain that the factors which can cause electrical fire go well beyond the simple explanation of short circuit with many of them closely linked to poor power quality in the electrical network. In this article, we focus on factors that lead to poor power quality and which in turn could lead to electrical fires in the network, based on frequency, severity and duration of presence. ELECTRICAL FIRE – GRASPING THE MENACE!The loss of lives and risks to business from electrical fires is much more serious than we would imagine.

|

It is also alarming to observe that sources for electrical fires is also expanding rapidly.

- For instance, over the last year, the Server room of Mantralaya building and that in a prestigious bank in a plush region in Mumbai were gutted in fire, with the cause again attributed to short circuit.

The risks to loss of valuable data, costly infrastructure and business continuity lure high with high instances of electrical fire.

POOR POWER QUALITY INCREASING THE RISK OF ELECTRICAL FIREBefore we analyse the factors, it is important to understand that the electrical fires are in most cases a direct result of overheating in the electrical networks. This article therefore limits the discussion to the factors that predominantly are created by poor Power Quality and lead to excessive or prolonged heating of the cables, equipment or components, thereby substantially increasing the risks of electrical fires in the electrical network. Harmonics Harmonics are nothing but the higher frequency currents which can generate heat in the electrical system. The non-linear loads such as computers, lamp ballasts, switch-mode power supplies, office equipment and transformers on low loads produce third order harmonic currents, named triplen, which are in the phase of all the supply phases. The third harmonic adds in the neutral in a 3-phase system which causes the neutral conductor to overheat. Excessive Thermal Insulation Overload need not always mean more than normal loads in the electrical network. The overloads can be a result of phenomenon such as a poor Power Factor, which leads to higher kVA drawn, and at a constant voltage that equates to higher current flow and heating. Over current protection devices are used as the main protection to arrest such overload. However, if the over current devices fail to operate the high current will lead to overheating of excessive insulation. Construction of the wire/cable, natural convection cooling and the current flow will determine the effective temperature to which a wire or cable will rise due to flow of current. Controlled experiments have shown that, it takes a 300 – 700% overload to cause ignition in absence of excessive thermal insulation. However, in practice, its often noticed that the prolonged overheating has led to the insulation degradation, causing ignition of the cable at a much smaller overload. Voltage surges Prolonged exposure to voltage surges in the electrical network can cause failure of sensitive electronic equipment as well as the wiring in the equipment. Often, the wiring insulation in sensitive electronic equipment fails because of frequent heating and subsequent cooling caused by voltage surges, thereby increasing the risk of sparks or electrical fire. Addition of new loads |

The electrical network in industries and commercial buildings is a living system. Over time, new equipment are installed with most often the electrical environment remaining the same. A much required re-consideration while adding new loads, in terms of ability of the network to support the new load with respect to original electrical design or the existing health of the network to bear the newly loads, is hardly taken-up. Though the system may tend to operate without risk to safety or performance initially, the problems in the form of overheating of cables, equipment due to new loads, tend to surface over a period of time. Accidental fires with a lag of 3 to 6 months are not uncommon in electrical networks which have taken-in significantly higher new loads, than what it was designed for initially.

Poor connections and Earthing

Undoubtedly, the biggest and most common cause

High-resistance connections are the most common cause of electrical fires. Loose connections cause the copper wire to be exposed to air and react with oxygen. The resulting copper oxides are more resistive than copper. Because of high resistance heat is generated which encourages more oxidation. A well-developed oxide can reach 30-40 watts on a 15-20 ampere circuit and that is hot enough to ignite fire. A loose conductor termination is capable of causing arcing and can also result in a potential fire hazard.

Electrical Fire Risks from Renewable Systems

Ensuring safety while pursuing sustainable operation to save the earth

The renewable energy systems (SPV or Windmills) operate at unity power factor. Such systems when connected to grid, leads to lower power factor at the load end, as the part of the active power (otherwise provided from the grid) is met through the source of renewable energy. But since the power supply capacity of renewable energy systems is less than the load at consumer end, and the grid supplying balance active power, while maintaining the same amount of reactive power to the connected load. The poor PF in turn leads to problems such as heating of components in the electrical network, thereby increasing the risks of fire. Besides in solar systems the temperature below solar panels and at aggregator are generally high. This added with high ambient temperature can cause thermal deterioration of cables and wires if not chosen right at time of installation. Use of inverters and automatic switching systems as per the standards are recommended to minimize the risks of fire hazards in renewable energy systems.

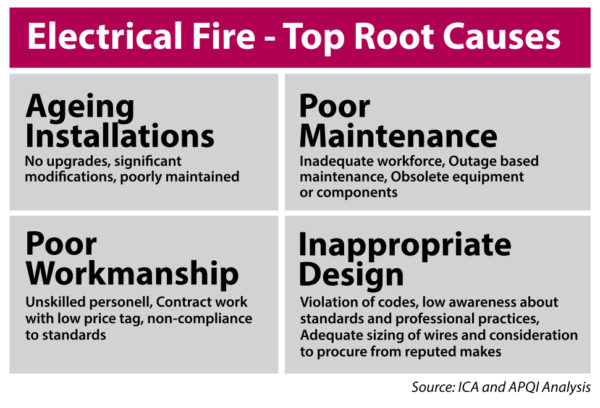

WHEN COSTS MEAN MORE THAN THE RISKSLack of adherence to standards in design and the tendency to procure the low-cost devices for power distribution, without the assessment of risks to safety, remains the untold cause behind most electrical fires, either caused by poor PQ or other factors. While statistics published in various studies, have time and again, highlighted the severity of the menace of electrical fire, what’s more worrying in context of electrical fires is the continued inclination to save costs over increased risks. Whether its unskilled workmanship, poor maintenance, non-compliance to regulations or ignorance of standards, prioritizing cost savings at every cost translate to the high risks to lives and property from electrical fire, in every field. PREVENTING ELECTRICAL FIRES ARISING FROM POOR POWER QUALITY |

- Power Quality studies along with thermal imaging are highly helpful in understanding the potential overheating in the electrical network.

- Periodic measurements and monitoring of harmonic distortion help in early identification and prevention of the heating in the electrical cables.

- Deteriorating connections can cause voltage sags which are dangerous for the system. A comprehensive power quality study can uncover wiring problems on-the-ground and thus help to avoid fire hazards.

- In case of non-linear loads, harmonics can raise to high level causing severe out-of-balance conditions. Use of 3+1 core cables is beneficial in such electrical systems to handle the imbalance. 3+1 core cables, owing to their larger surface area, help in reducing the hot spots thereby reducing the risk of electrical fires.

- Triplen Harmonic Filters helps to minimize the electrical fire risks emanating in infrastructure with heavy IT/ITeS, Building Automation with non-linear loads, Computational Infrastructure, UPS Batteries etc.

- Monitoring the power quality regularly and taking required actions on the findings can help in mitigating the fire risk

CONCLUSION

When it comes to the news, Electrical fires are mostly seen as accidents, caused by the inevitable short circuit, which in turn is a result of anything between ignorance to bad luck. In reality, electrical fires are also a result of slow and gradual built-up created by poor power quality issues. The relatively lower awareness, difficulties in spotting, understanding and correcting Power Quality issues and the sheer number of issues itself makes it challenging to pin poor Power Quality as a cause for electrical fire. With increasing non-linear loads in the electrical systems, the electrical fire safety is at a greater risk, particularly from the Power Quality issues. It is about time that the risks created by poor Power Quality are monitored and minimised on priority and with regular frequency. That’s one of the most assured way to proactively prevent the electrical fires.

REFERENCES

- https://www.fluke.com/en-in/learn/blog/electrical/test-and-measurements-for-electrical-fire-prevention

- https://www.iafss.org/publications/fss/9/3/view/fss_9-3.pdf

- https://electrical-engineering-portal.com/selection-of-number-of-cable-cores-with-emphasis-on-sizing-parameters

- https://timesofindia.indiatimes.com/city/mumbai/city-ranks-2nd-in-short-circuit-fires-with-418-deaths-in-10-years-ncrb/articleshow/62406828.cms

- https://www.indiatoday.in/india/story/in-6-months-mumbai-has-seen-12-major-fires-22-deaths-1259486-2018-06-13

- https://timesofindia.indiatimes.com/city/mumbai/server-room-fire-lays-bare-poor-renovation-in-mantralaya/articleshow/61938061.cms