Published On: Aug 25, 2020

Digitization is one of the drivers to improve efficiency, reliability and quality of the electrical network. But it’s a double-edged sword. While digitization enables miniaturization it also demands the same from every other element of the electrical network – may it be the smart grid or the VFD/ASDs or LED lights. The quest to miniaturization of electronics, accommodated in a compact space is often at the core of EMC/EMI issues.

INTRODUCTION

The use of power electronics is the fundamental driver of miniaturization and is evident across most modernised equipment in the electrical network.

The increased use of power electronics is everywhere – starting from the growth of smart grid technologies as well as power technologies for renewables up to energy efficiency improvement initiatives.

- Growth in IT infrastructure in every domain, use of dense digital consoles, increasing automation also sees greater use of power electronics.

- Wind and solar power are other examples which use power electronics.

- Electric vehicle is another fast-emerging domain which relies on power electronics, digitization and miniaturization of electrical systems to make its progress.

Practically, in each of these technology applications, the electrical energy is passing power electronics and creating an EMC/EMI issues in different magnitudes. If not addressed appropriately, there are several unforeseen implications – including Power Quality issues which is the most prominent amongst all.

The modern switching-mode power electronics systems generate a wide spectrum of electromagnetic interference (EMI). This EMI can create several critical issues in the normal operation of other electronics systems and must be suppressed to an acceptable level before it hurts.

The noise from EMI is traditionally classified into two types – differential mode (DM) or common mode (CM) noise.

- DM noise owes its source to current within the power delivery paths

- CM noise owes its sources to the current between the ground and the power circuits.

EMI is a very vast topic in itself and requires in-depth know-how, continuous research and at times a highly localised approach as the solution. In this blog, we particularly focus on EMI propagation, measurement, EMI standards in India in view of improvement of the Power Quality (PQ).

EMIs AND WHERE DO THEY COME FROM?

In dictionary terms, EMI is a noise. Technically, it is defined as the Electrical line noise. Essentially, the noise from Radio Frequency Interference (RFI) and Electromagnetic Interference (EMI) causes unwanted effects in the circuits of different systems.

Sources of the problems could include:

Motors, relays, motor control devices, transmission devices, radiation from microwave appliances, and other sources. RFI, EMI and other frequency problems can lead to severe consequences including equipment to lock-up, loss and errors in data, malfunctioning and reduced life of sensitive electronics in the network.

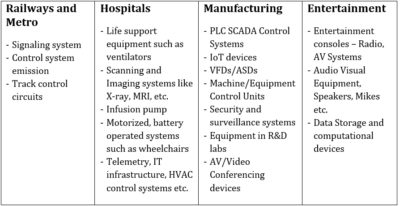

several ways based on their source, transmission mode, and the nature of disturbance.

|

Examples of EMIs in various fields: Generation and characterization of EMI noises can be done in The interference from an electromagnetic signal in the circuit depends on three factors. The magnitude and type of signal, the transmission of signal from source to receiver and the impact on the receiver. Several other factors such as impedance, presence of magnetic and electric fields, usage patterns etc. affect the circuit. The time-varying electric fields are known to impact the high impedance circuits as compared to the same type of magnetic field which predominantly affect the low-impedance circuits. |

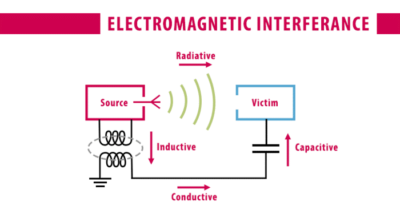

The noise can plant itself into the circuit in three ways: conduction, induction from near-field devices or phenomenon and radiation (usually, far from the field).

|

Typically, conduction is the type of interference observed in case of multiple equipment sharing a common power supply and grounding path. Such designs are demanded by facilities that need to economize very highly on the space and therefore share power supply. Near-field induction also known as common mode interference can occur due to two factors. First, the Inductive coupling which is a result of two conductors, usually wires, where, because of their configuration a change in flow of current in one wire induces a voltage across the edges of the other wires. This induced voltage is the noise which can disrupt or interfere with the equipment in the circuit. Capacitive coupling, the second type, results from energy transfer within a circuit usually caused by the capacitance between two circuit noes. |

In case of far field induction, the frequencies involved are of 3 MHz or greater. In such cases, the wavelength is lower, and the induction field is predominant out to 15 meters. Example of this would be broadcast or radio transmitters.

EMI estimation is not always easy and an experienced, practical know-how is usually required to calculate and arrive at its accurate measurement.

EMI PROPOGATION – REASONS BEHIND THE RISE

Several factors could contribute to the EMI propagation at different levels in the power distribution systems. Here, we attempt to highlight the most prominent of the factors that could lead to poor PQ phenomenon with its roots in EMI. The phenomenon of how changes in power systems have impacted the emissions, the immunity and the transfer of EMI disturbances is also discussed briefly.

In the grid and production environment, several factors could be leading to greater EMIs:

Production environment

- Shift to smaller units connected to LV and MV loads with miniaturizations of machines and devices

- Smaller, computational and data driven devices

- Use of Solar and Wind power as a primary source of power

- Changes of machine interfaces from synchronous machines to those with power electronic interfaces (HMIs) and the shift to active power electronic interfaces

- Greater use of Energy efficient equipment and devices including VFDs, LEDs, Energy efficient Motors etc.

Grid Environment

- Underground cables

- Power-line communication

- Greater use of protection and control in the power distribution

- Smart grid – using intelligent support and information systems for its functioning

Overall, increasing adoption of distributed generation and the non-linear loads which use power electronics interfaced devices are an important cause of waveform distortion. These lead to high levels of harmonic content, mostly of higher frequencies, with flicker and other issues resulting in poor PQ. While greater use of power electronics provides benefits such as increased efficiency, lesser cost, and compact size to name a few, with use of proper technology these same equipment can be employed to compliment the mission and mitigate issues due to waveform distortion.

Typical examples of rise in EMIs and its impact on the modern electrical network

Power switching

The quest for ultra-compact, efficient power conversion has meant increasing use of techniques such as high-speed semiconductor (IGBT) switches or pulse width modulation (PWM) in order to generate fast rise time voltage pulses of the appropriate duration and polarity. A flip side of this leads to significant problems for OEMs, System Integrators in the form of EMIs creating issues in functional performance to total damages in severe cases.

Leakage currents

The noise referred to in EMIs is due to a magnetic field that is developed in between the power system (a VSD, for instance) and the ground. Between the system and the ground includes small capacitive couplings. At higher frequencies, the inductance of these capacitances is low and as a result, stray currents will flow making it the leakage currents.

EMI STANDARDS AND SCENARIO IN INDIA

EMIs are largely a product phenomenon. Whether it’s a cable or a data storage device using magnets, if designed for controlled EMI emissions, the problem of EMI noise can be curtailed right at the source. In this view, standards governing the EMI emissions and their role in product approvals play a vital role.

In India, the product evaluation for Electromagnetic Compatibility has its roots in various National / International Standards. The recommended tests include Conducted Susceptibility (CS), Conducted Emission (CE), Radiated Emission (RE) and Radiated Susceptibility (RS) and other standards.

The EMI/EMC test services defined by NABL in accordance with ISO/IEC 17025 for its EMI-EMC Services. The testing centers in India typically get listing and recognition from various international bodies such as TÜV Rheinland, TÜV SÜD, Det Norske Veritas (DNV), EMITECH France, Intertek, Canadian Standards Association (CSA), Underwriters Laboratories Inc. (UL) etc.

The challenges in EMI Standards

- The EMI/EMC tests are not compulsory and the legal framework for the same is yet not clearly laid out

- Lack of know-how at the product development company end is also a key hurdle

- Relatively less or no importance is given the EMI/EMC aspects during the product development

- Generally, it is observed that the product designers wait until the very last stage of the design to get the testing and validation for EMIs. This limits the implementation of standards as any modifications required will demand redesign, reconsideration of components etc. making the cost-overruns and time delays inevitable

- As an ecosystem – eliminating EMIs could be challenging owing to multiple standards, on-field issues and lack of standards compliance in dependent components

While several studies highlight the importance of EMIs in improving PQ in context of India, the general lack of awareness on EMI, PQ and their respective standards has meant the electrical networks are still vulnerable in many ways.

PQ AND EMC – THE FREQUECY OVERLAPS AND SOLUTION OVERVIEW

EMI Frequency Range

EMC deals with a frequency range from DC to 400 GHz. However, the following ranges are recommended from a practical point of view:

|

An undefined area from 2.5/3 kHz to 150 kHz should not be categorized as noise-free but the particular range of frequency will not lead to non-compliant equipment or cause any functional issues.

The PQ issues are observed in the lower frequency range and on the higher side there is a strong overlap with the EMC. While EMC can be considered as one of the parts of overall power quality in many ways the same logic could apply to solutions for EMC and PQ as well.

Solution overview

To reduce EMCs and thereby the resulting PQ issues several solutions can be used.

- Reactors and filters can be used in various locations in a power drive system. These include in line with the power input (line reactor), in the DC link between the rectifier and capacitor (DC link choke) and at the drive output to the motor (motor reactor).

- To increase the reliability and operational safety dv/dt chokes and filters (low inductance, Motor chokes (increased inductance, better signal smoothing, Sinusoidal output filters are used for specific scenarios. Additionally, a range of connectors, cable assemblies and other related accessories may be considered to aid the EMI reduction.

- Ground impedance must be retained low and at the current frequency of the anticipated interference event. A wide ground strap or plane can be used to reduce impedances.

The solution for EMI problems and fixing the PQ issues arising from it involves a customised approach to suit the specific needs. There is a range of approaches to the solution starting from following good quality and compliant design and procurement practices to solving the EMIs incurred on the site through specific solutions.

Generally, the solutions to EMIs, if not bought as a package of the equipment, are difficult to superimpose at a later stage. It is recommended that you buy an equipment that has built-in compliance with the EMIs.

CONCLUSION

Since power electronics relies on high voltages and high current processing through fast switching to reduce losses it also becomes a significant source of electromagnetic noise. The magnetic interference in power systems is termed noise. The noise is a result of magnetic field developed somewhere along the power system which travel to sensitive equipment causing numerous unwanted problems.

In line with the above, the designing of every power electronic equipment requires to address three major issues – losses, EMI and harmonics. Addressing these issues involves dealing with uncertainties and therefore affect the costs, size, efficiency, quality and performance. In fact, designing a power electronic equipment is in many ways a process to achieve a highly balanced and nuanced trade-off between the factors above.

EMI issues are difficult to detect in a live environment and solving these too could be complex, often demanding changes in key distribution and protection infrastructures such as cables and grounding. The best way to arrest PQ issues due to EMIs is to filter them through stringent compliance find them at the earliest (preferably before they occur).

To address EMI issues, understanding the sources and root causes is the key. The efficacy of the solution is a direct result of accuracy in understanding the problem at source.

REFERENCES

- Center for Electromagnetics India – https://cem.sameer.gov.in/Services.html

- Discussion on Noise and EMIs – https://qte.com/pages/resources/white-papers/electromagnetic-interference.html

- PQ and EMI issues in Smart Grids – Report by Joint Working Group – http://cired.net/uploads/default/files/final-report-C4.24-CIRED.pdf

- EMI and PQ – https://cpes.vt.edu/research/areaemi

- A review of common PQ problems in Electrical Networks – http://www.rroij.com/open-access/a-review-of-power-qualityproblems-and-solutions-inelectrical-power-system.php?aid=42532

- PQ due to EMI issues – https://www.schaffner.com/fileadmin/media/downloads/brochure/Schaffner_Brochure_Basics_in_EMC_and_power_quality.pdf