Published On: Apr 20, 2017

Power Quality issues are most common & faced by most of the industries. Ignoring the symptoms of possible PQ issues existing in the electrical system could lead to damaged equipment, consequently reducing its working efficiency and shortening the life span. Therefore, the diagnosis of Power Quality is important for equipment safety, occupational safety as well as energy utilisation efficiency. PQ Audit provides a technical and economic basis to help, make informed decisions in solving power related problem and thus enhance the electrical system performance.

pManifold, National Support Network (NSN) partner of APQI recently interviewed Mr. Pradeep Prabhu, an industry expert from Apollo Tyres Ltd. India to understand his viewpoints on ‘Achieving reduction in financial losses through comprehensive PQ Audit’. (The views here are personal, and not to be associated with any company in any forms.)

Q 1. Please let us know about your role in your company.

A. I am presently responsible for the Energy Portfolio, for the tyre manufacturing process of Apollo Plants globally.

Key Roles, Responsibilities:

- To identify & deploy Synergy projects with energy controllers at plants,

- To improve specific energy consumption at work centres by following guidelines of EnMS (50001) standard, adaptability of latest energy efficient technology for capex projects

- To look into opportunity to optimize unit cost by having a mix of energy sources.

Q 2. Please help us understand in brief about your manufacturing facility.

A. For someone who has never seen a tyre manufacturing process it will be a very interesting thing to hear and understand. Tyre manufacturing is a very simple process where rubber (synthetic/natural) in proportion is mixed with chemicals to arrive in a sheet form which is then calendared to either fabric or wires based on the type of tire to be produced. This along with nylon fabric/steel wires, steel wire sheets etc. are assembled in automatic machines to make it cylindrical in shape. The assembled tire called as “green tire” then goes through a vulcanization process where this is put in mould to get its shape along with letters, design and markings.

Q 3. How power quality is important for your facility?

A. The manufacturing process consists of a mix of automatic mixing, assembly equipment’s having ac & dc drives connected to motors, plc, hmi, sensors, electronic cards, tyre uniformity check equipment’s etc. to ensure safe operations, accurate assembly and best quality of the finished product. Quality of power supplied plays a crucial role with respect to reducing sporadic failures, interruptions in auto operations during scheduled machine change overs, shutdown, start-up etc. Most of the critical assembly equipment’s require rated and good quality power with in prescribed range & tolerances.

Q 4. What are the key PQ challenges/gaps you were facing in your facility?

A. As Engineer’s, having years of experience in our kitty related to specific industry, we are always coherent and biased in our actions. Certain critical parameters, tolerance level, installation criteria we neglect at first instance. Added to this as the utilization of the equipment’s increase at location, sporadic failures start creeping into the daily routine which makes the life always firefighting. This starts making you work like a machine in itself running from pillar to post across the plant where failures become a new normal in life. I had a similar experience working at plant for about 2-3 years about a decade back, until we started thinking differently as all product suppliers used to confirm their product is good

Q 5. What was the approach and steps undertaken by you to mitigate PQ issues?

A. We did critical analysis of failures for equipment where the loss was huge. Single component was identified to go in depth study with real time monitoring. Vendor was roped in too. To our surprise we could gather data related to intermittent variation in electrical parameters due to loads running at other sections being fed from the same distribution board. This was a breakthrough for us which again we simulated at other machines where failures were high. Finally moving up the ladder we ended to transformer secondary of a typical distribution system where we noticed current and voltage harmonic levels beyond the prescribed IEEE limits and amplifying too at times. This made us to look for ways to eliminate the not required once! by means of installing filters to nullify the effect of these.

Q 6. What are the key benefits achieved focusing on below points?

Return on investment, Payback, Savings in O&M, reliability etc.

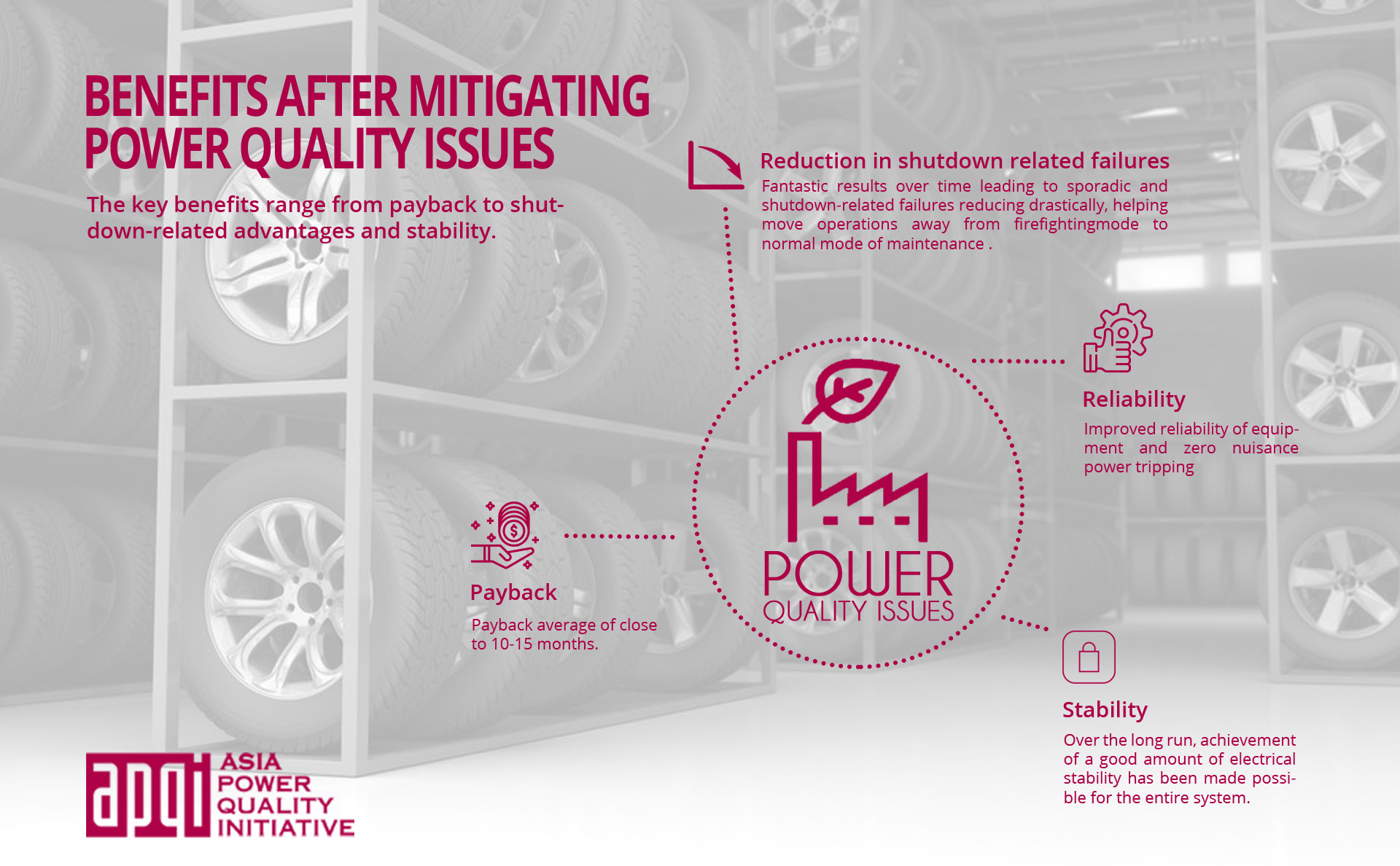

A. The Capital investment for these filters was high and to take a call to go ahead was a difficult one. But we marched ahead in a phased manner covering one after the other transformer. Results were fantastic over a period of time with sporadic & shutdown related failures reducing drastically. Slowly life coming back to normal from firefighting mode of maintenance. We got a payback average of close to 10-15 months with improved reliability of equipment’s and zero nuisance power tripping. Experience with HF led us to deploy it in critical distribution boards across at plant. Now over the years this is installed horizontally at multiple plants and locations in India. A good amount of electrical stability has creeped in system

Q 7. What message would you to like to give to fellow industry professionals to improve PQ environment?

A. Someone needs to drive this in organisation and take risk. PQ environment is to be measured when the base load of plant reaches close to 50% plus or at places with lot of electronic components, drives etc., do the study and install HF filters to mitigate the harmful harmonics from power system. Lastly the most important one being selecting the right product for your location without being pulled into to buy fancy products available in market.