Published On: Feb 02, 2017

|

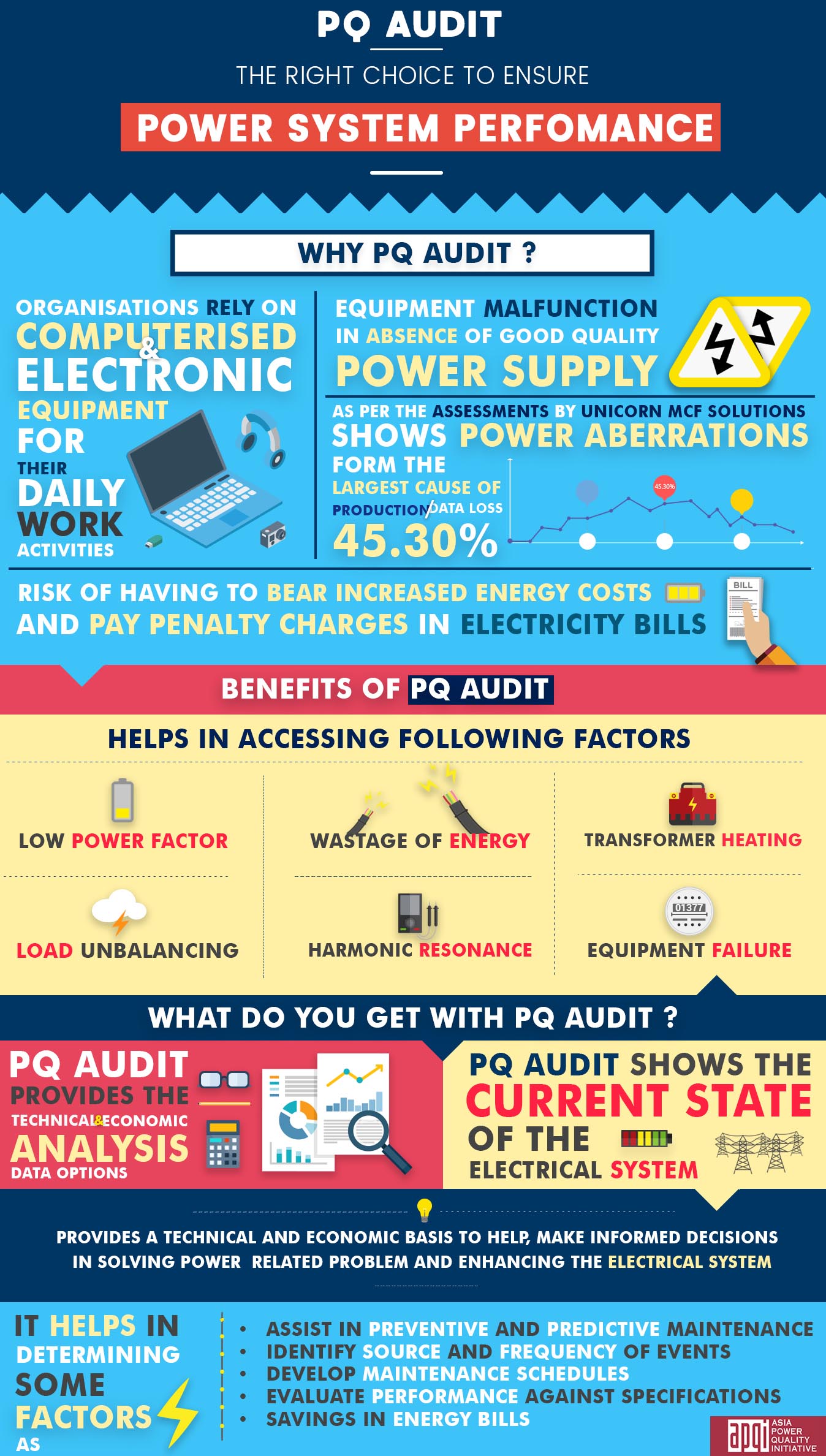

Economic decisions in any setting are based on the information available at the time the decision is made. If decisions are to be consistent, the information used in the decision process must be reliable. A common way to ensure reliability of information is to have some type of verification performed by an independent entity, typically called as an audit. Audits provide third party assurance to various stakeholders that the subject matter is free from material misstatement and closer to reality. As a result, stakeholders may effectively evaluate and improve the effectiveness of risk management, control, and the governance process over the subject matter. In the Energy sector, energy auditing is one such important technique performed in accomplishing an effective energy management program to improve the energy efficiency and reduce the energy operating costs. This technique is used to establish a pattern of energy use, identify how & where losses are occurring and suggest appropriate economically viable engineering solutions to enhance energy efficiency in the system. While energy audit is being done regularly to assess the energy quantity and flow, a similar audit to assess the quality of power is not as widespread. Without appropriate quality of power, an electrical device (or load) may malfunction, fail prematurely or not operate at all. There are various causes due to which power supply can have poor quality like in sustained out of standard voltage or frequency profile, frequent appearance of unwanted and unnoticed issues like transient voltages & currents, harmonic pollution etc. leading to increased power consumption, heating of equipment & wiring, malfunction and even damage. This blog highlights the importance of Power Quality Audit to measure the quality of power supply and thereby take corrective actions leading to saving of time & money. WHY PQ AUDIT?It is almost assumed that quality electrical power supply must be available at all times, always within the frequency & magnitude tolerance limits and with a perfectly sinusoidal waveform in case of alternating current (A.C) systems. Business & industrial organisations, public authorities, hospitals, laboratories, banking & finance groups, etc. are relying more and more on computerised and electronic equipment for their daily work activities. Such equipment and related processed data can malfunction or get damaged in absence of good quality power supply. Thus, a reliable, efficient and safe power supply is essential for guaranteeing productivity and smooth functioning of any organisation. |

As per the assessments by Unicorn MCF Solutions in association with EU-APQI, ICAI & FICCI, Power aberrations form the largest cause of productions/data loss, i.e. 45.30% as compared to other causes of fire or explosion, hardware or software error, and others. Ignoring the symptoms of possible PQ issues existing in the electrical system could lead to damaged equipment, consequently reducing its working efficiency and shortening the life span. The resulting break in critical processes (i.e. machine downtime) could also lead to a loss of earnings or opportunity that could far outweigh the mere cost of the actual operation.

In addition, there is also the likely risk of having to bear increased energy costs and pay penalty charges in electricity bills, with the possibility of legal disputes with energy providers. Therefore, due to the unawareness of poor PQ, the diagnosis of Power Quality is important for equipment safety, occupational safety as well as energy utilisation efficiency.

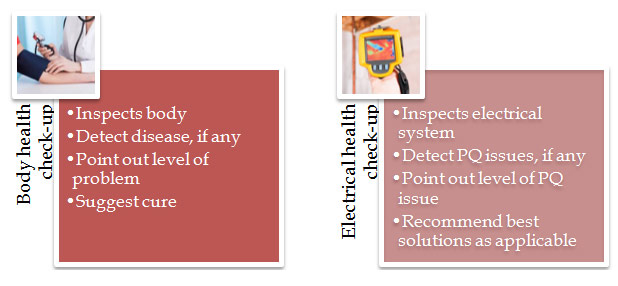

PQ Audit provides a technical and economic basis to help, make informed decisions in solving power related problem and enhancing the electrical system. The audit provides a structured hierarchical step-by-step approach to tackling utility and end-user power quality challenges. It is analogous to a body check-up by a doctor.

"Power aberrations form the largest cause of production/data loss (i.e. 45.30%)"

BENEFITS OF PQ AUDIT

|

The quality of power supply can be improved by working at various levels namely at user’s electrical system, equipment connected to the system and mains. If the problem is in the electrical system, the PQ Audit could advise the user to improve or enhance the existing electrical system infrastructure, install active or passive filters, harmonic compensators, emergency generators or UPS systems, or to intervene directly on the system structure (transformers, new distribution lines, etc.) with fresh design. If the problem lies in the source or electricity mains, the PQ Audit may encourage the customer to contact the provider in order to improve the supply contract parameters or even explore regulatory intervention in meeting ‘Standards of Performance ‘set for the utilities. PQ Audit thus makes it possible to find the right arrangement within the system. |

PQ Audit focuses on common issues such as harmonic distortion, low voltage, voltage sags, unbalanced loads, wiring and grounding, energy wastage on unoccupied space and poor power factor. The audit also helps in identifying and assessing below major problems causing PQ issues.

Hence, it distinctively helps in understanding what type of PQ issues are going on at various locations within the system and how are they affecting the electrical system.

What do you get with a PQ Audit?

A PQ Audit provides the technical and economic analysis data options & the information needed to help make an informed decision to address PQ issues. If one conducts a detailed PQ Audit, it should provide a report showing a complete picture of the electrical system’s correct state of operation like health diagnostics. It lists all the measures to be taken promptly when disturbances are detected before the negative impact on production and the running of the equipment is felt. This report also includes a summary of recommendations on power conditioning equipment (voltage regulator, isolation transformer, UPS, Filters etc.), Cost range, type & rating of recommended equipment and calculated purchase payback of power conditioning equipment.

Below are some of the key benefits of PQ audit that provide an excellent foundation for more analysis and effective power system design.

- Assist in preventive and predictive maintenance

- Identify source and frequency of events

- Establish precise location and timing of events

- Develop maintenance schedules

- Monitor and trend conditions

- Analyze harmonics, Flicker, Transients frequency variation, voltage variations (sag & swell)

- Ensure equipment performance

- Assess sensitivity of process equipment to disturbances

- Evaluate performance against specifications

- Savings in energy bills

Thus, PQ audit help in improving system efficiency, reduction in equipment failure, better production rate & quality thereby enhancing the life of the electrical network.

CASE STUDY

Problem statement: A magnet wire plant load was approximately 5 MVA and was fed from three 2-MVA transformers. In addition to the wire lines, other important process sections of the plant include a rod mill and enamel, lubricant, and mechanical-room systems. It experienced voltage-sag-related process upsets on several of its wire manufacturing lines.

Solution: In order to decrease the susceptibility of the plant to power quality (PQ) disturbances, the local utility supplying the magnet wire plant requested a PQ audit service provider to provide a detailed PQ audit. For the plant, a scoring system was used to evaluate the susceptibility of various manufacturing lines in the plant to power quality disturbances. Under the audit process, several assessments were done and their validation was tested. The audit recommended all possible options with particular emphasis on low-cost modifications by changing AC drive firmware and adding small power conditioners to control circuits in the plant.

Solution: In order to decrease the susceptibility of the plant to power quality (PQ) disturbances, the local utility supplying the magnet wire plant requested a PQ audit service provider to provide a detailed PQ audit. For the plant, a scoring system was used to evaluate the susceptibility of various manufacturing lines in the plant to power quality disturbances. Under the audit process, several assessments were done and their validation was tested. The audit recommended all possible options with particular emphasis on low-cost modifications by changing AC drive firmware and adding small power conditioners to control circuits in the plant.

CONCLUSION

Power Quality assessment is also important along with Power Quantity assessments (Energy Audit). With the rising PQ issues, a right choice for their reduction will be PQ Audit! It will lend a helping hand to the utility or a facility facing serious PQ issues. It will additionally help in the diagnosis of any on-going energy losses due to poor PQ or any safety concern for equipment life as an occupational safety. By using PQ audit, one can identify potential problems, plan & take corrective measures, and prevent facility downtime, saving both time & money. As PQ audits can be undertaken by industry and utility, hence interventions for improvement can be made without dependency on the consumer or the network interventions. If you are an industry or a utility, a PQ audit at your organization is a highly recommended first step towards enabling quality power.

References

- Introduction to Auditing

- CIM-Power Quality Audit, Maximizing the highest power quality in your system, by SOCOMEC

- PQ Audit by Power Quebec Audit

- Need of Power Quality Audit in Mission critical facilities by Saju. S.K, 14th October,2011

- Why power quality audit is important? by PM-Electronics

- A review of power quality problems and solutions in electrical power system by R K Rojin

- Power Quality Audit by Power Quality engineering