Published On: Jul 19, 2015

Power Quality (PQ) plays a significant role in efficient power delivery and its utilization. Its significance is accentuated from the fact that poor power quality i.e. non conformityof voltage, harmonics and frequency may lead to huge damages (at times irreparable) at both the utility and the customers end. The deteriorationof power qualityis a huge concern because of the increase in the use of power electronic devices using inverters, unbalanced loads like large furnaces or rectifiers, and a complicated power distribution network with increased grid connections for new energy sources, etc.

Power supply network problems caused by poor PQ are a common problem for both electric power suppliers and users. However, it is not easy to identify whether the cause of poor power supply quality is at the utilitiesendor at the end of the users. Hence, power quality Measurement& Verification (M&V)at each end is necessary to understand the actual causes of power quality problems and to design effective countermeasures.Astheclassic business adage goes”you can’t manage what you haven’t measured”, and it certainly holds true for power quality. This blog attempts to focus on the need& importance of M&V for assessing or monitoring PQ by its key stakeholders (i.e. Utilities and End-users).

NEED OF CONTINUOUS POWER QUALITY MEASUREMENT IN TODAY’S DIGITAL ENVIRONMENT BY UTILITIES

While the global digital economy is redefining business operations, it is also setting new standards for electric power reliability and quality requirements. Downtime is undesirable for any business and even the smallest interruption or power quality event can cause equipment failure, data loss or lost revenue. Specifically for consumers in India, supply interruptions and low voltage levels are a constant source of concern. Utility companies recognize these problems and are now moving towards making investments to improve Power Quality (PQ), however these improvements are coupled withtariff increases.There is a need to verify if real PQ improvements have been made, for which effective measurement of the supply quality is crucial.Measurement also helps track the sources of interruptions and enable comparisons of PQ at various locations.

|

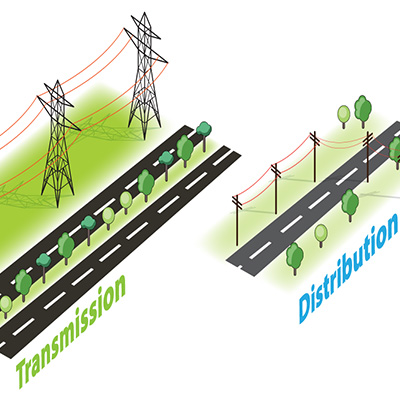

IEC 61000-4-30 is an International Electro-technical Commission(IEC) standard that defines the correct measuring algorithms for power quality instruments.It stipulates how power quality should be measured, and measuring instruments certified to be in compliance with IEC61000-4-30 would have reliable and repeatable measurement results regardless of the original manufacturer.The standard covers various PQ parameters like power frequency, supply voltage amplitude (RMS value), flicker, dip/swell/interruption of supply voltage, transient overvoltage, supply voltage unbalance, harmonic voltage, inter-harmonic voltage, signaling on supply voltage, and rapid voltage fluctuation. Requirement of defining M&V framework by Utilities Red dotsin above figure indicates M&V equipment placement across the power value chain. Redundancy at all levels of the electric-power system reduces the incidence and duration of disturbances. |

|

Further, today most discoms have high-end SCADA/DMS systems, ABT meters, etc. in place for consumers with some threshold Contract Demand; however still in existing revenue metering protocol PQ monitoring aspect is not recognized at all. There is a need for discoms to evaluate and consider PQ monitoring in their tariff structure to incentivize or penalize consumers.

For ex. In June 2013, Tamil Nadu Electricity Regulatory Commission (TNERC) in its Tariff schedule has imposed strict penalties on HT customers for harmonic level violations beyond the permissible limits specified by CEA regulations. For more details on how developing countries like India now need to develop favorable policies and measure PQ performance parameters on a continuous basis, read our blog: Policy Landscape Around PQ In India, Compared With Other Rising Economies

HOW MEASUREMENT CANBE DONE?

Continuous improvement is a strategy, not a tactic. Meters that can provide ongoing monitoring of both short-term and ongoing power-quality issues cost more than those that simply monitor usage and time of use, so they should be installed where they add the most value. One good option is: at a facility’s main service-entry point, where the equipment can help managers/supervisors determine if disturbances are coming from the energy supply or are being generated onsite.Several measurement tools/equipment are available for PQ measurementwhich includes,

- Multi-metersare: the basic equipment to measure voltage and/or current. It measures overloading of circuits, under and over voltage issues, and unbalances between circuits, etc.

- Oscilloscopes: are valuable when performing real time measurements. By looking at the voltage and current waveforms, an observer can look for distortions and detect any major variations in the signals

- Disturbance Analyzers: can typically measure a wide variety of system disturbances from very short duration transient voltages to long duration outages or under-voltages.

- Further, there can be different types of this: Conventional Analyzers & Graphics based Analyzers

- Data loggers

- As harmonic distortion is a continuous phenomena, selection of Harmonic Analyzers requires carefulevaluation to be able to meet basic requirements like voltage & current simultaneous measurement, magnitude & phase angle measurement of individual harmonics, ability to characterize statistical nature of harmonic distortion levels, etc.

NEED OF THE HOUR–ENDUSERS CO-OPERATION FOR PQ M&V

Power quality disturbances have significant financial consequences for end users also, in addition to the impact on the Utilities. Hence, it is very critical and important to upfront consider measurement & verification to minimize possible PQ issues in an industrial unit.For mission-critical applications where communications and connectivity are essential elements of operation, power-monitoring instrumentation can greatly improve the performance of a facility’s power systems infrastructure. End users must understand health of his own system and take some of the following preemptive steps to prevent economic loss or safety hazard.

- Proactive management of power resources: the continuous capture of all events enables end-users to develop trend lines and algorithms to maintain real-time illustrations of infrastructure performance and improve reliability, while automated alerting sends alarms to power managers before problems occur.

- Reliability-based monitoring approach: the value and longevity of power conditioning and mitigation equipment can be optimized by a reliability-based monitoring approach using power quality monitoring instrumentation.

- Early detection of problems: problems can be detected before they cause damage through benchmarking that sends alerts when conditions begin to deteriorate. For contract negotiations, monitoring the data serves todocument power quality and demand profiles for utilities or energy service providers.

- Troubleshooting: Power monitoring instrumentation has been designed to help identify the nature and severity of power quality problems to prevent them from recurring. Automated software can pinpoint the location, magnitude and duration of events to quickly remedy harmful situations.

- Routine: checks by company appointed professionals to assess the power quality and load monitoring measures undertaken at the customer’s load end.

CONCLUSION

Systematic procedures for monitoring power quality concerns can be developed but they must include all levels of the system, from the transmission system to the end user facilities. Power quality issues show up as impacts within the end user facility but may involve interaction between all levels of the system.A consistent set of definitions for different types of power quality variations are the starting point fordeveloping evaluation procedures. Thesedefinitions allowstandardized measurements and verification across different systems.

A data analysis system for power quality measurements should be able to process data from a variety of instruments and support a range of applications for processing data. With continuous power quality monitoring, it is very important to be able to summarize variations with time trends and statistics, in addition to characterizing individual events.

M&V procedures and their implementation can suitably help identification of PQ issues before they occur and hence allow corrective actions. This would result in power systems and their operation become safer, reliable and efficient – which is the desired win-win situation for all stakeholders.

REFERENCES

- Interpretation and Analysis of Power Quality Measurements – Christopher J. Melhorn & Mark F. McGranaghan, Electrotek Concepts, Inc., Knoxville, Tennessee

- Power Quality: Measuring to Manage – Schneider Electric Power Management

- The importance of IEC 61000-4-30 Class A for the Coordination of Power Quality Levels – Ing. Mag. (FH) Robert Neumann, Product Manager – Power Quality Qualitrol LLC, Belfast, United Kingdom

- Guidebook for Power Quality Measurement – Hoiki E. E. Corporation

- Power Quality Analysis Teams with Energy Audits to Enhance Facility Uptime – By Ross IgnallDranetz