Published On: May 01, 2020

From the outside, Warehouses may appear to be a quiet, uneventful and simple places to manage. But in reality, and from the inside, Warehouses are large and complex systems in terms of managing its power distribution reliably and in energy efficient manner. Other than the hustle and bustle at the hub, managing warehouse efficiently calls for highly reliable and efficient systems inside. The spaces are large, manpower is less, goods are costly and reliability of movement mostly controlled by automation is critical. Together, this puts a lot of stress on the existing resources, including power.

For Warehouse Managers, PQ Management may come lower in the list of priority. However, the risk of warehouse facility’s exposure to poor PQ is high. The increasing use of LED Lights, conveyor based movement of goods, power electronics in CCTV and surveillance systems, automated stacking and environment control measures are common to every modern warehouse. All these have one more thing common- the potential to adversely affect the PQ and therefore the reliability of a Warehouse’s functioning. In this view, PQ issues in Warehouses need to be understood and given greater importance.

INTRODUCTION

Like in most other industries, in warehouses too, the importance of electricity is realized when its absent. The biggest challenge in terms of PQ is ever evolving and dynamic nature of warehouses. To begin with, many warehouses may not be designed from a perspective of serving warehousing operations. At times, these are idle manufacturing spaces converted to warehouses, or sometimes even a leased makeshift facility or existing space is accommodated to function as a warehouse. This also means, the electrical systems are often poorly prepared to deliver the intended reliability required at the warehouse. Many a times, facilities are subjected to ‘creative’ solutions by “blending” new lighting fixtures, control devices, and branch circuits to transform it into a warehouse. This is nothing but a faulty foundation threatening the safety and reliability of electrical power network. Electrical fire safety of warehouses is also under question with increasing instances of fire in warehouses in recent times.

Warehouse fires on the rise, as observed in recent news

While most of the news do not mention the cause or casually term it as a short circuit, the role of poor PQ cannot be easily ruled out. Lack of awareness on how poor PQ can lead to electrical fires is a key reason for lack of clear attribution to the cause of fire.

Most warehouse facilities are now adopting solar microgrid technologies, to reduce energy costs. This too, is affecting the PQ adversely. Overall, many small issues, legacy and modernisation, can lead to a poor PQ in the warehouse and create a difficult situation for its reliable functioning.

WHATS TRENDING IN WAREHOUSES? AND HOW IT IMPACTS PQ?

As India marches on a firm trajectory of economic growth, warehousing, which is a key component of supply chain is witnessing a steady growth. It is estimated that over the next five years, this sector will attract an investment of around $ 10 billion. While warehouses are a critical part of the economy, power is a critical part of warehouse functioning. From applications such as cold storage to machines such as conveyor belts to facilitate faster delivery, power is the backbone of warehouses.

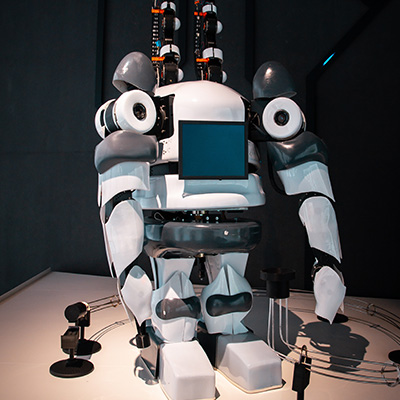

At the same time, warehouses in India are also making a leap in terms of technology. From conveyor belts to robots, Indian warehousing is looking to embrace automation in its operations like never before. Automation also means higher and better-quality power requirements. Even so, automation lowers day-to-day operating costs and thus generates savings in the long run. That said, warehouses in India continue to battle with several power quality issues that prevent them from reaching their full potential. Here, we reflect upon some of the PQ issues before emerging smart warehouses and ways to address them.

Profile of a typical mega-scale warehouse in the USA

- Areas 8.5 million sq. ft.

- 11 miles of conveyor systems

- Everything is moved on either floor robots, conveyor belts, or elevators

- Computer routing systems to establish the most efficient path for the product to the customer

- Racking and shelving systems

- Conveyors and sorting systems

- Mezzanine flooring systems

- RFID, QR Code and Bar Code Scanning

Every element of the warehouse is dependent on reliable power. Power quality, which drives the reliability of power in the warehouse, is critical to achieve the key performance metrics expected at the fulfillment center.

WAREHOUSE SYSTEMS AND POWER QUALITY

The warehouses are dependent on advances in technology to enable smooth process improvements in order picking, routing, throughput speed and distribution/dispatch of the orders. All these requires absolute reliability at every step. Power quality issues can be detrimental to the continuous and reliable operations. With increasing warehouse size and scale of operations, improving the energy efficiency is also a major goal. Although limited, Power Quality improvements have a vital role in aiding the energy efficiency goals too.

Here we consider how Power Quality impacts critical systems in warehouses:

PQ issues due to Material Handling automation in warehouse

Motors and VFDs, a key element in almost every material handling equipment in the warehouse, are a major source of power quality issues. Also, another complexity in case of warehouses is the increasing level of automation – which means more VFDs in the system over a period of time. VFDs cause harmonics in the electrical network and therefore needs appropriate mitigation strategy to ensure good PQ.

The appropriate product can avoid system pollution but for existing system harmonic solution will depend on several factors including design and installation of the systems. If relatively low harmonic content is observed, the addition of simple passive filters will lead to good PQ. If the excess harmonics are high and the warehouse involves several VFDs, installation of an active filter is probably most appropriate. Another possibility is even a small number of VFDs leading to high harmonics where installing drives with active front-ends probably is the best solution.

PQ issues due to LED Lights in warehouse

LED lights are replacing the traditional high mast lamps typical to the warehouses. However, the other side of LED lights that is the PQ issues they create collectively on system level are often given less importance in comparison to the energy saving benefits. LED lights are now recognised source of polluting the PQ with high THD (Total Harmonic Distortion), low Power Factor and high Inrush currents.

In many instances, warehouses are located close to the manufacturing center. This leads to further complexity as non-linear loads in CNC Machines, Furnaces, Robots, Welding etc. become a major source of harmonics pollution and thereby affect the performance of LEDs. It is not uncommon to observe flickers or disturbances in LED lights of the warehouse, when they are located close to the manufacturing centre.

In order to ensure a true realization of key benefits of LED Lights, that is, saving power, lower maintenance and longer life, the parameters affecting the PQ must be carefully considered before investing. Selecting the right LED driver package can have a significant impact on the PQ.

PQ issues due to faulty earthing and grounding

Faulty grounding, especially due to poor design or workmanship, leads to power quality issues in warehouses. As discussed in the introduction, in many instances, spaces otherwise not utilised for value-added purposes such as manufacturing are converted to warehouses. In other cases, the quality of workmanship, materials in order to keep the cost to a bare minimum are a key reason for poor earthing and grounding. Whatever could be the reason, impact in terms of poor PQ is significant and often observed as high leakage currents.

For instance, the good grounding system allows all equipment to have the same reference voltage. This in turn helps the sensitive electronic systems in operation such as controls, sensors, scanners etc. by preventing the flow of objectionable currents in communication lines, seals and other connections.

Good earthing and grounding is therefore critical to avoid data losses, corrupt controls and ensure reliable and safe functioning of the automated environment.

HVAC, Refrigeration (Cold Storage) leading to PQ issues in warehouse

New types of freezers with highly energy efficient motors, compressors and advanced controls for temperatures, alarms etc. use highly sensitive electronics. While the design of such freezers may be in perfect synergy, even small sags in voltage (indicator of poor PQ) can lead to shut down or damage. Such cases are observed especially in facilities that are turned into cold storage, but not designed and built originally for the purpose. Also, expansion or upgrade of existing set-up often leads to the freezers not able to withstand the poor PQ as compared to the earlier systems. Adding adequate protection devices, control transformer to even out the load and eliminate sags should solve the problem.

HVAC systems use a large number of VFDs and therefore lead to poor PQ. Chillers or condensers in individual units lead to harmonics and therefore need to be monitored and compensated appropriately to maintain good PQ. Like most industries, in warehouses too, the focus is mostly on addressing the energy efficiency issues in HVAC and Cold Storage facilities. However, reliable operation and performance of these systems need a thorough assessment and monitoring of PQ parameters on a continuous basis.

PQ issues from Rooftop Solar PV in warehouses

Warehouses typically have large areas of unutilised rooftop space, ideal for Solar PV. Given their remote location, Warehouses may also be in off-grid locations, making them depend on diesel power. As a result, Rooftop solar PV holds several benefits for warehouses. Solar power can serve all the loads for Warehouses including, lighting, refrigeration and simple material handling. But PQ issues emanating from Solar power is one constraint that the must be considered as well for reliable power.

Environmental and system design conditions are important to the functioning of the PV systems. Both these can have a significant impact on the efficiency and power quality if the warehouse. The key challenge is the variable power flow due to the fluctuation of solar irradiance, temperature and type of power semiconductor devices. Good power quality, characterized by a sinusoidal voltage and current output, from a solar PV system is critical to voltage sag and swell.

CONCLUSION

Concurrent with the advances in logistics automation, there has been a steady evolution of awareness to efficiently manage energy utilization and capitalize on savings. Comparatively, the Designers, Planners, Contractors and Managers of Warehouses have paid little or no attention to the PQ aspect. In many instances, acquiring budgets for upgrading the facility to safeguard PQ are not available. Considerations in design of warehouses, standards for compliance when procuring key equipment or paying a premium for quality workmanship are inadequate to ensure a good PQ. While there are warehouses now using low-voltage variable speed drives, techniques being deployed to avoid simultaneous peaks, integrated energy management systems etc., the number is quite low.

Warehouses are key to reliability of supply chain and PQ is key to reliability of achieving fulfilment commitment of the warehouse. It is about time to commit financial resources to improve PQ and thereby achieve a higher level of reliability and safety for the warehouses where loss of opportunity or loss of image can create big impact on the brand itself.

REFERENCES

- What Technology Does Amazon Use In Their Fulfillment Centers? –

- The Case of the Flickering Warehouse – https://www.ecmweb.com/content/article/20894099/the-case-of-the-flickering-warehouse

- Warehouse OSHA Guidelines – https://www.thebalancesmb.com/warehouse-safety-2221202

- Building Guide for Warehouses – https://www.wbdg.org/building-types/warehouse

- Rooftop Solar for Warehouses – http://www.solarmango.com/sector/warehouses