Published On: Jan 31, 2019

With the increasing use of sensitive electronic equipment and addition of non-linear loads including renewable energy grids, continuous PQ monitoring is emerging as the only way to reliably and accurately spot PQ issues.

INTRODUCTION

Uninterrupted power is a very important goal for every facility and achieving the highest reliability for power systems requires a foresight. But, in most cases, the challenges that risk the reliability of power systems are only understood in hindsight. Good Power Quality (PQ) is critical to ensuring the highest reliability in any power network. Whether it’s voltage spikes, harmonics or interruptions that last for only for a few milliseconds, the PQ issues can damage equipment, create nuisance disruptions in day-to-day operations and in worst cases pose a severe risk to safety and reliability of power systems as a whole. Investments in continuous PQ Monitoring must be a priority given its benefits at several levels.

THE TREND TOWARDS CONTINUOUS PQ MONITORING

Traditionally, PQ monitoring is performed on a case-to-case basis using field studies and portable devices to measure key parameters affecting PQ. The traditional approach to solve the problems and generally improve the PQ have been reactionary.

With advanced devices and cloud-based storage, it is now possible to monitor and assess PQ at Utility or Customer level on a continual basis.

Typically, most modern BMS (Building Management Solutions) used in high-rise or commercial buildings come with a comprehensive range of centralised dashboards with distributed monitoring systems for power/ energy, security, fire and safety etc. However, monitoring and assessment of critical parameters concerning the Power Quality remains outside the technological and functional purview of monitoring frameworks of a typical BMS.

Permanently installed modern Power Quality monitors are built for continual monitoring with software to handle automated data collection, intelligent processing and actionable representation of results. The software is equipped to monitor and analyse a real-time performance as well as develop a long-term summary of performance based on the stored data. Such systems, integrated with a BMS have the potential to unravel insights that help to correlate problems observed on the surface with its underlying root causes in the electrical network.

In fact, continuous monitoring of PQ is probably the only way ahead to accurately monitor and analyse the issues arising due to poor PQ.

HOW PQ MONITORING IS DIFFERENT FROM POWER SYSTEM MONITORING

The systems to monitor performance of equipment or energy efficiency on a run-time basis typically do not operate on a bandwidth that is required to capture the PQ events. The PQ events are multi-faceted and often occur in a very short span of time ranging from a microsecond to just a couple of seconds. A typical PQ Monitoring system therefore needs to capture and analyse data from multiple sources, often starting from the power source to its distribution points and forward.

CONTINUOUS PQ MONITORING - KEY BENEFITS

Continuous PQ monitoring aims to discover targeted answers to the most critical risks to reliability of power systems and thus delivers several tangible benefits.

Proactive management: Continuous monitoring by its very nature enables users to spot the trends and easily extrapolate the risks to safety and reliability within specific points in the electrical network. With availability of intelligent alerts, the Managers are well-informed to take proactive measures.

Aids preventative and predictive maintenance: The insights into how the equipment reacts to specific PQ events or disturbances provides the foresight for taking timely remedial actions. It also allows the Maintenance teams to optimise the preventive maintenance window by providing previously unavailable insights. Specific procedures to avoid interruptions, prevent failures can be designed based on data from continual monitoring.

With diagnostic capabilities for specific conditions, PQ monitoring can create a huge impact on development of preventive maintenance programs.

Early detection of problems: By benchmarking PQ parameters specific to the network, systems can identify and send alerts when conditions begin to deteriorate. Problems arising due to poor PQ can be detected early on, that is, before they cause damage.

Improved energy efficiency: Specific co-relations on impact of poor PQ on energy reduction measures is possible with continual PQ Monitoring. The energy load profiles can be tracked, analysed and co-related with PQ events to evaluate impact on consumption and crate an internal ‘standard’ to drive the energy efficiency programs.

Accurate planning for capital investment to improve PQ: The trends from real-time and historical data provide accurate information for planning of capital investments – whether its adding or upgrading critical assets or solutions to mitigate poor PQ. Further, continual PQ monitoring also helps to track the difference in PQ by creating before/after analysis and suggest a reliable view on ROI.

Ensuring Compliance: The compliance and regulatory checklist for PQ parameters has been only expanding. PQ is also an important part of several internal quality control programs, industry-specific norms and international standards. Granular information feeds obtained from Continual PQ monitoring makes it easy to spot and arrest the non-compliance.

CONTINUOUS PQ MONITORING TOOL-KIT

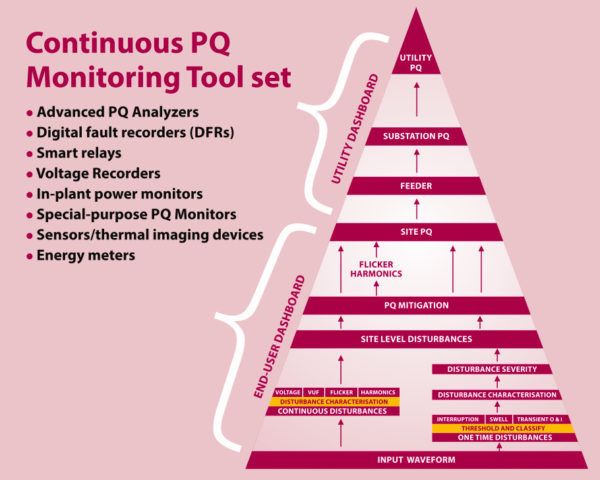

Effective use of Continuous PQ Monitoring demands a new set of tools, communication interfaces and data processing systems as compared to the traditional methods of monitoring PQ.

Some key PQ measurement tools include:

- Advanced PQ Analyzers – the backbone of continuous PQ Monitoring

- Digital fault recorders (DFRs) – trigger on fault events and record the voltage and current waveforms that characterize the event

- Smart relays

- Voltage Recorders

- In-plant power monitors

- Special-purpose PQ Monitors

- Customized systems with specialized sensors/thermal imaging devices

- Energy meters

The tools above are backed by local and cloud-storage capabilities, computational infrastructure and a host of compatible communication devices including modems, routers, cables and more.

Power Quality Data Interchange Format (PQDIF)One of the key goals of PQ Monitoring is to be able to establish a benchmark for PQ, whether it’s across the facility or at an industry level. As Utilities and Customers adopt Continuous PQ Monitoring, a diverse range of PQ software applications, underlying database platforms, logics to run simulations and analyse data are emerging. The Power Quality Data Interchange Platform (PQDIF) specifies a common format for PQ measurement. The IEEE Power Engineering Society Task Force is standardising the data interchange format. The guidance provided by the neutral platform is key to ensuring consistent format of data exchange between software and monitoring devices for its universal applicability. |

CONSUMER CENTRIC SERVICE CONTRACTS WITH CONTINUOUS PQ MONITORING

SAIFI, SAIDI, MAIFI are some of the indices used to measure distribution system reliability. However, with traditional methods of PQ Monitoring, it is relatively difficult to leverage these indices to improve reliability of power systems. For instance,

SAIFI = SUM (Connected load of feeder X Number of sustained interruptions of this feeder in the month) / (Total connected load on all feeders)

The SAIFI indices cannot be used to compare reliability for two utilities with different feeders. The indices generates an average value using weighted total number of feeder interruptions, i.e the sum of individual feeder interruption weighted by the proportion of load it carries. Also, a significant proportion of interruptions are caused due to faults at the Customer end. Lack of granular data on utility performance hamper the ability of the customers to earn better contract terms from power distribution companies. With continuous PQ monitoring systems, way more accurate instances can be easily traced and analysed to improve the performance and get flexible contracts that reward customers maintaining good PQ.

CONCLUSION

Issues and disturbances in electrical networks arising due to Poor PQ are the root-cause of several business problems including productivity losses, downtime, loss of reputation and good-will, customer dissatisfaction and much more. The quality of electrical power is an important contributing factor to the development of any country and this can be achieved through continuous power quality monitoring which helps detect, record and prevent power quality problems. The historical data collected through continuous PQ monitoring systems can be leveraged to build predictive maintenance models for vital assets using advanced data analytics technologies.

Continuous Power Quality monitoring provides a real-time “Health Check” of a facility’s power system and must be viewed as a vital and integrated part of power system to maintain its reliability. However, given the traditional reactionary approach to measure, analyse and improve PQ, it is still viewed as an additional cost by most stakeholders.

The relatively high level of investments in establishing a continuous PQ Monitoring infrastructure is one of the biggest concerns when it comes to widespread adoption. However, with falling computational costs and large-scale availability of economical options to monitor PQ, the trend in continuous monitoring will only continue to rise.

REFERENCES

- Power quality monitoring as integrated with distribution automation – https://ieeexplore.ieee.org/document/943460

- Advantage of Using Power Quality Recorder with Continuous Waveform Recording – https://www.elspec-ltd.com/advanced-use-of-continues-waveform-power-quality-analyzer/

- About the Power Quality Data Interchange Format (PQDIF) – http://www.pqmonitoring.com/papers/pqdif.pdf

- What are SAIFI, SAIDI AND MAIFI? – http://mahadiscom.com/emagazine/mar06/what%20are%20saifi.shtm