Published On: Dec 20, 2018

How investments in LEDs designed and manufactured with quality parts and adherence to standards can help to earn longer life and better PQ.

INTRODUCTION

The blog – LED Lights, Boon or a Bane?, published recently, delved upon the dark side of LED Lights, especially its impact on PQ environment. The Blog also touched upon the importance of assessment and mitigation of PQ challenges that are typically associated with LED Lights. However, the blog also observed that most LED luminaire and Driver manufacturers, as well as Consultants and the internal procurement teams, are not fully aware and equipped to overcome the PQ problems in the electrical networks. Given this, high level of caution and study must be conducted before making large investments in LED Lighting systems for greenfield or retrofit projects.

While there are numerous resources and an abundance of expertise available in selecting the right type of LED Lights for your goals or applications, this blog, particularly highlights the traps and issues related to PQ, that are commonly overlooked, while making large scale investments in LEDs. Additionally, it draws upon some of the recommended practices to ensure good PQ while using LED Lights.

PQ parameters may differ significantly with LED Make

Several analytical studies conducted to observe the harmonics generated in LEDs, have shown that there could be significant difference between the percentage of total harmonic distortion of current (%THDi) for various brands of LED Drivers used with these lights. Typically, LED Drivers are a part of the package when buying LED Lights. It is thus important to understand the impact of LED Drivers that are provided with the LED Lights, in order to minimise the impact on PQ.

PQ ISSUES IN LEDs AND DRIVERS

The root causes for PQ problems arising and affecting the LED Lighting Systems can be mostly traced to the synchronous working of LED lights with its Driver devices. In the sections below we identify and provide solutions to the dominant PQ issues observed in electrical networks with high density of LED Lighting systems.

PQ Issues in LED Drivers

LED Driver is primarily a switching device and therefore, inevitably, becomes a source of harmonic and/or electromagnetic interference (EMI) in the electrical network. Essentially, there are two types of LED Drivers – those with a constant current output and those that give constant voltage output. Harmonics are observed in both types of LED Drivers. LED Driver Circuits are available in a dizzying range with options of electronics such as diodes, capacitors, resistors to converters delivering varying levels of efficiency and PF correction. In case of LED Drivers, disturbances in PQ are mostly attributed to three factors as below:

|

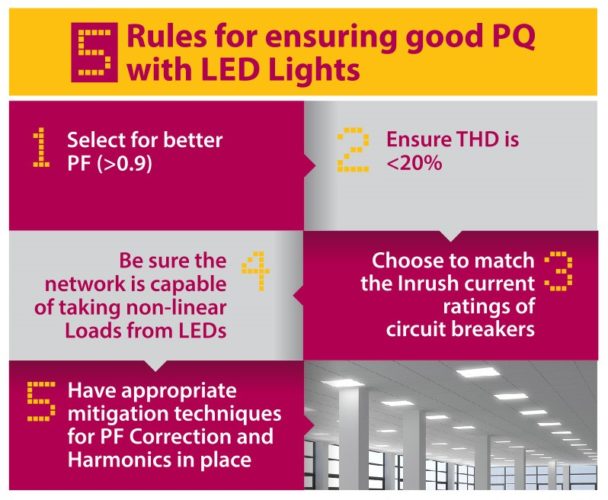

Total Harmonic Distortion (THD) must be <20% Simply put, THD is the distortion of the sinusoidal waveform, typically observed when there are non-linear loads in the electrical network. THDs, in case of LED Lights, lead to damage of LED Drivers from overheating, and in worst cases even a complete burnout. For longer life of the LED Driver and a healthy electrical network, THD of the LED Drivers must be less than 20%. Power Factor must be >0.9 While not every LED Driver will mention PF, it is undoubtedly a highly critical parameter. From a practical consideration, PF embodies the quality of real power delivered to the facility and the power detected and billed by an energy meter for the load. A PF of less than 0.9 may attract penalties from the utility company. EN61000-3-2 requires that LED power supplies have a power factor of >0.9. |

Usually, the specifications for LED Drivers mention ‘normal Power Factor’ which could mean a PF below 0.9. While investing in large volume (quantity) of LED Lights (and Drivers), utmost care must be taken to ensure the PF of the driver is a minimum of 0.9 or more. If one is not able to get the details, such measurements on random samples, before going for lot, must be carried on the site to gain an understanding of the PF values.

|

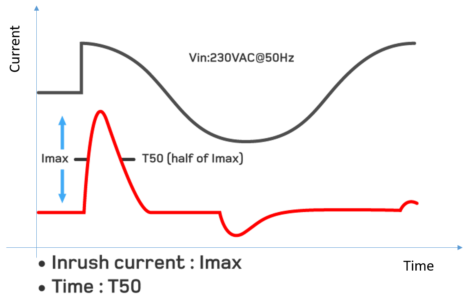

InRush Currents calculations are a must Nuisance tripping of MCBs is a common phenomenon in facilities with high density of LED Lights. The high inrush on LEDs can cause these products to fail, by welding the relay contacts. More caution and care must be exercised in case of retrofits, to ensure that the equipment are rated suitably to withstand the LED inrush current. The figure shows the nature of the inrush current and its peak, IMAX. T50 is the time duration in which the inrush current pulse is equal to 50% of IMAX. It shows an example of inrush current (IMAX) and T50 times for a typical LED driver. Source: LED Driver Inrush Currents (https://adlt.com.au/%EF%BB%BFled-driver-inrush-currents/) |

Inrush currents in LEDs are created due to the filters on the input and bulk capacitors on the output side of an LED Driver. It is observed as an input current for a very short time to charge the capacitors during the start-up. However, the current has a much higher amplitude (70 to 100 times) as compared to the steady-state current, usually being worst during the first half-cycle. Depending on their type and make, circuit breakers have different inrush trip curves. It is advisable to find and understand the trip curve of the circuit breaker and carry coordination or check its values against the inrush current specified by the LED Driver manufacturer to ensure uninterrupted power supply.

THE ADVANTAGES OF SELECTING LED LIGHTS THAT DELIVER BETTER PQ

Stepping up energy savings

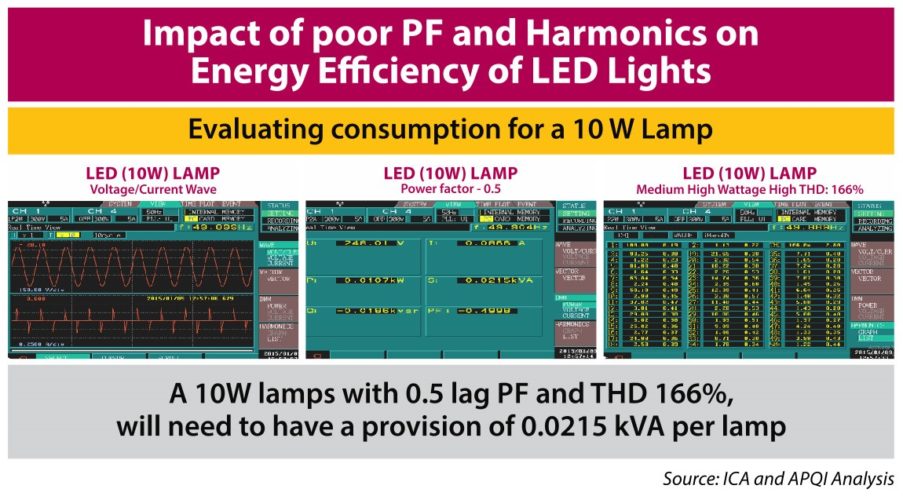

While most of the energy savings in LED Lights are achieved due to their significantly lower Power consumption as compared to other technologies, it still leaves the scope for last mile savings lost due to poor PF. A low/poor PF in LED Lights equals inefficiency as the light draws more current that what is utilised by the load.

For example,

10 Watt LED bulb with PF of 0.4 means a consumption of 25 VA burden from system

10 Watt LED bulb with PF of 0.8 means a consumption of 12.5 VA burden from system

This may be insignificant in a domestic set-up, but attains reasonable proportions for LED Lights used for street lighting or industrial illumination. With a higher PF in LED Drivers, these last mile savings can also be effectively realised.

Savings from optimised electrical components

LED Lights with higher PF also helps to minimize the current capacity of components, especially dimmers and cables in large set ups, as the lights do not draw on excess current. These, when appropriate factored in the lighting design, can lead to significant savings in initial investment for the electrical network equipment.

Longer life for Lights and Drivers

The life of a LED Driver is closely related to the temperature it is exposed to. While the Drivers are designed to withstand a range of high external environment temperatures, it’s the excess heat generated inside the Driver circuit that can be fatal to its life. Excessive heating is a direct result of presence of high level of harmonics in the LED Driver. Typically, lower the harmonics, lesser the heating and generally results in a longer life for the LED Drivers and the lights.

Safe, reliable and healthy electrical networks

Harmonics, poor PF and Inrush Currents emanating from LED Lighting systems could lead to a range of problems from nuisance tripping to electrical fires (in extreme cases). Given the technology in LED Lights, it may not be possible to prevent the presence of harmonics, poor PF and Inrush currents, but following the right standards and selection criteria will help to control the adverse impact from these factors. A calculated and conscious selection of LED Lights to arrest the PQ issues guarantees a safe, reliable and healthy electrical networks.

CONCLUSION

In order to ensure a true realisation of key benefits of LED Lights, that is, saving power, lower maintenance and longer life, the parameters affecting the PQ must be carefully considered before investing. Selecting the right LED driver package can have a significant impact on the PQ.

PQ Standards and Enforcement for LED Lights in India

|

Source: Report on Power Quality of Electricity Supply to the Consumers by Forum of Regulators; Highlights from the Presentations of Shri. Venkatesh Dwivedi, Representative of EESL

Given relatively lower awareness levels among stakeholders, the enforcement of PQ improvement standards continues to be the key challenge. With this, it is essentially upon the End Users to understand, assess and monitor the LED Lights for their performance with respect to the PQ. An informed and calculated decision is the first step to arrest the PQ problems arising out of LED Lights.

REFERENCES

- https://www.powerelectronicsnews.com/technology/the-three-ps-of-led-driver-selection

- Mom Ref: 8(49)/2012-IPHW, Government of India, Ministry of Communications and Information Technology

- LED Driver Inrush Currents – https://adlt.com.au/%EF%BB%BFled-driver-inrush-currents/

- LEDs Magazine, Simplifying the sophisticated: LED driver selection made easy

- Report on Power Quality of Electricity Supply to the Consumers by Forum of Regulators – http://www.forumofregulators.gov.in/Data/Reports/Power07.pdf